As my vinyl collection has grown my storage options have evolved with it. Currentyly I’m using a three-tier shelf made with half-inch MDF. What I’ve noticed is that once a shelf is full it begins to sag in the middle. Being paranoid as I am just a few degrees of flex makes me uncomfortable so the kernel to build a replacement began to grow. I had intended to do some other projects before building the shelves but still decided to do preliminary research. First I looked into existing designs that were available for purchase. This way I had a reference for what typical pricing is as well as inspiration for my own solution.

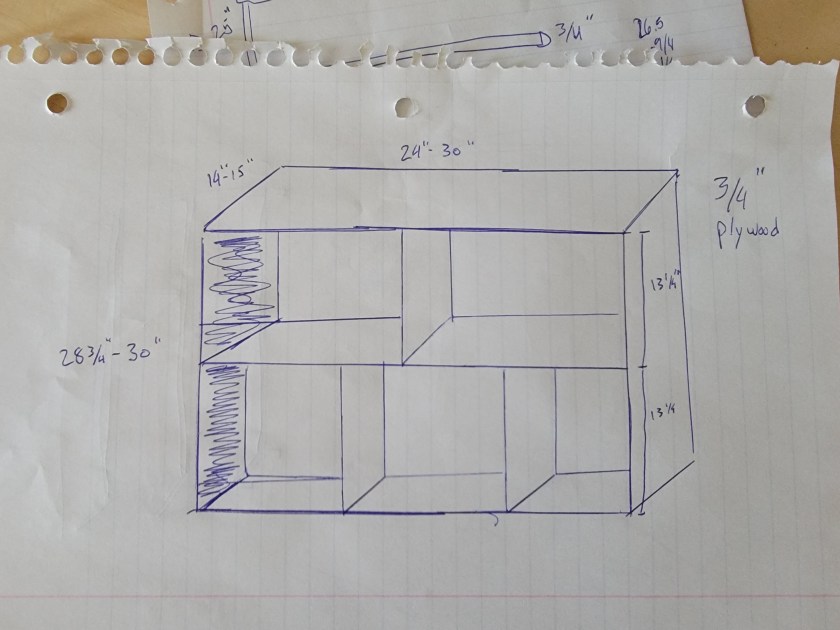

From there I started sketching out ideas and getting reference measurements from my existing storage. Vinyl albums are 12 3/4″ square and my shelving has 1/2″ of allowance and I kept that distance, giving shelves 13 1/4″ of vertical space. At a minimum the shelves would be 26 1/2″ for two tiers, plus any overlap with the top and bottom (two 3/4″ pieces). This meant a height of 28 3/4″ for me. My turntable is between 14-15 inches long so I wanted the shelves to atleast be that deep, and my current shelves are 24″ wide so I wanted at least that. So I decided at minimum it should be 14″ x 24″ x 28 3/4″ (LxWxH). Once I’d settled on a design, complete with measurements, I moved onto pricing out the materials. This is when I caved and decided to go for it as my other projects would be more expensive. To make this happen I found some affordable 3/4″ cherry plywood sheets that I could order pre-cut, saving me hours of hand sawing and heartbreak (I don’t expect to cut very straight with my current saw).

I mentioned this to my dad and sent a picture of my sketch. He suggested a Kreg pocket jig and asked how I’d handle the plywood’s exposed edge grain, I still don’t have an answer; maybe veneer tape. Some time later he actually called to confirm my plan and my measurements. This is also when he suggested I put a backboard on to help resist torsion. So I ordered my wood cut-to-size, a pocket hole jig, and a 1/4″ sheet to act as backing.

While waiting for pieces to arrive I did what research I could about assembling shelves, making/using pocket holes, really anything relevant that seemed worth my time.

Much to my relief the extra cuts from my cut-to-order were included so if I paid for a 8sqft I got 8sqft of plywood. I put the pieces together just to make sure the pieces actually fit flush, though I do admit if I were to re-design I’d go 15″ long and 30″ instead of 24″ wide. Hindight is 20/20 or atleast better than my natural eyesight. Before I did any drilling I practiced with my jig as I’d never used one (pocket hole jig) before, given I had some extra 3/4″ from my order it provided the needed material for practice. Not wanting to run the drill while the baby is sleeping I postponed assembly ’til the next day though I did continue to measure and draw in my drill spots.

With a 14″ length I decided 4″ in from each side was close enough to 1/3 to carry the burden. I ran a (too large) bead of wood glue at each joint before tightening down. Even though it put my pocket holes exterior I wanted the screws going into the “meat” of the wood. I used the 1 1/4″ coarse screws included with my jig kit.

I assembled it in halves first, then put the halves together. With the outside box finished I contemplated the dividers. Here’s where paper and real life differ: my drawing was wider than taller so the insinuated spacing for the dividers was actually much smaller in reality. Realizing this I adjusted to only a single divider for the bottom. I smeared the cut divider with a thin layer of glue before sliding it in and drilling the top in. It was then I noticed I hadn’t put in pocket holes in the bottom of the divider which now had a gap along the bottom. Miraculously I was able to put in an ad-hoc pocket hole inside the cramped shelf space without ruining all my labour.

Feeling very proud of myself I gave it some time to set while I trimmed a 1/4″ plywood sheet for a backboard. I glued the back face of the shelves and then lined up the back board on the corners. Then starting at the corners I hammered in 1 1/4″ nails to fasten it tight.

Structurally finished I called it a day and now ponder the final touches. I’ve wiped it down with a damp cloth but my next step is to sand the faces flush, wipe down again, likely stain and finally decide on how to cover the visible edge grain.